Precipitation Hardening Market: Assessment of Future Demand, Growth Trends, and Industry Prospects from 2025 to 2035

Overview:

The global precipitation hardening market is poised for substantial growth in the coming years. The market, valued at approximately USD 3.17 billion in 2025, is projected to reach USD 7.04 billion by 2035, reflecting a compound annual growth rate (CAGR) of 8.3% from 2025 to 2035. This expansion is driven by the increasing demand for high-strength materials across several key industries.

Precipitation hardening, also known as age hardening, is a heat treatment process used to increase the yield strength of malleable materials, including most structural alloys of aluminum, magnesium, nickel, titanium, and some steels and stainless steels. The process relies on alterations in solid solubility to produce strong, coherent precipitates that impede the movement of dislocations in a crystal’s lattice.

The aerospace sector is a significant end-use industry, benefiting from precipitation-hardened alloys in aircraft components due to their high strength-to-weight ratio. Similarly, the automotive industry utilizes these materials to enhance vehicle performance and safety. The oil and gas industry requires robust materials for equipment operating in harsh environments, further driving demand.

Geographically, North America, Europe, and Asia-Pacific are key regions in the precipitation hardening market. The presence of major manufacturing hubs and increasing investments in infrastructure development contribute to market growth in these regions. Emerging economies in Latin America and the Middle East & Africa also present growth opportunities.

Key players in this market include companies specializing in heat treatment services and material manufacturing. These companies are continuously innovating to develop advanced precipitation hardening techniques and materials tailored to specific industry needs. The competitive landscape is characterized by technological advancements and strategic collaborations.

The need for materials with enhanced mechanical properties and durability across diverse applications will continue to fuel the growth of the precipitation hardening market. Innovations in materials science and processing techniques are expected to further optimize the performance and applicability of precipitation-hardened alloys.

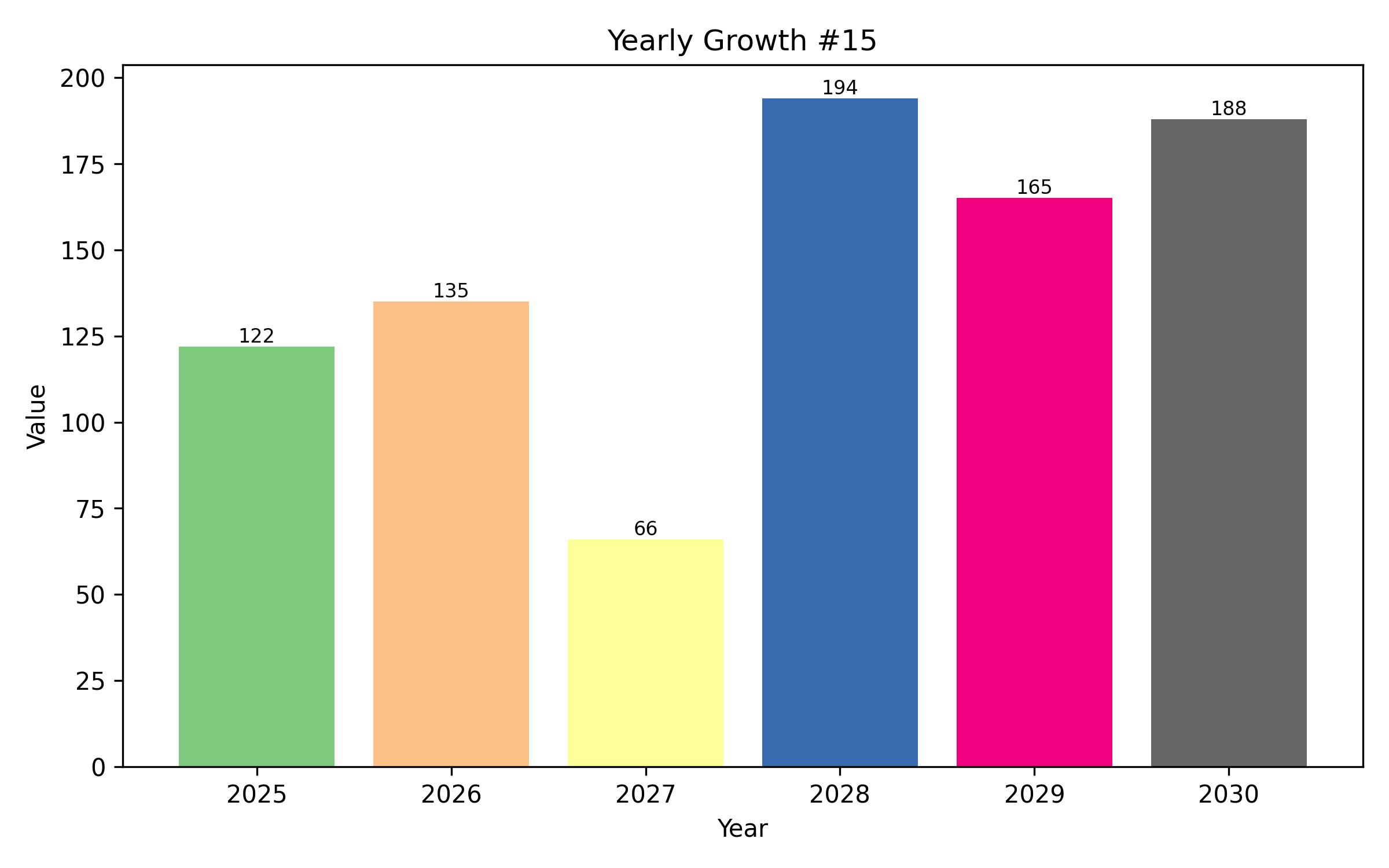

Year On Year Growth Chart

“`html

| Report Attribute | Details |

|---|---|

| Market Size in 2025 | USD 3.17 billion |

| Revenue Forecast for 2035 | USD 7.04 billion |

| Growth Rate (CAGR) | 8.3% from 2025 to 2035 |

| Base Year for Estimation | 2024 |

| Historical Data | 2020 – 2024 |

| Forecast Period | 2025 – 2035 |

| Quantitative Units | Revenue in USD million/billion and CAGR from 2025 to 2035 |

| Report Coverage | Revenue forecast, company market share, competitive landscape, growth factors, and trends |

| Covered Segments | Hardening type, material, end use, and region |

| Regional Scope | North America, Europe, Asia Pacific, Latin America, MEA |

| Country Scope | U.S., Canada, Mexico, U.K., Germany, Italy, Poland, China, India, Japan, Australia, South Korea, Brazil, UAE, KSA, South Africa |

| Key Companies Analyzed | Bodycote; Paulo; Wallwork Heat Treatment Ltd.; Pilkington Metal Finishing; Bluewater Thermal Solutions; MSL Heat Treatment Limited; Indo-German Vacu Treat Pvt. Ltd.; Irwin Automation Inc.; Pacific Metallurgical, Inc.; Thermex Metal Treating |

| Customization Options | Free report customization (up to 8 analysts working days) with purchase. Changes to country, regional, and segment scope |

| Pricing and Purchase Options | Customizable purchase options for tailored research needs |

“`

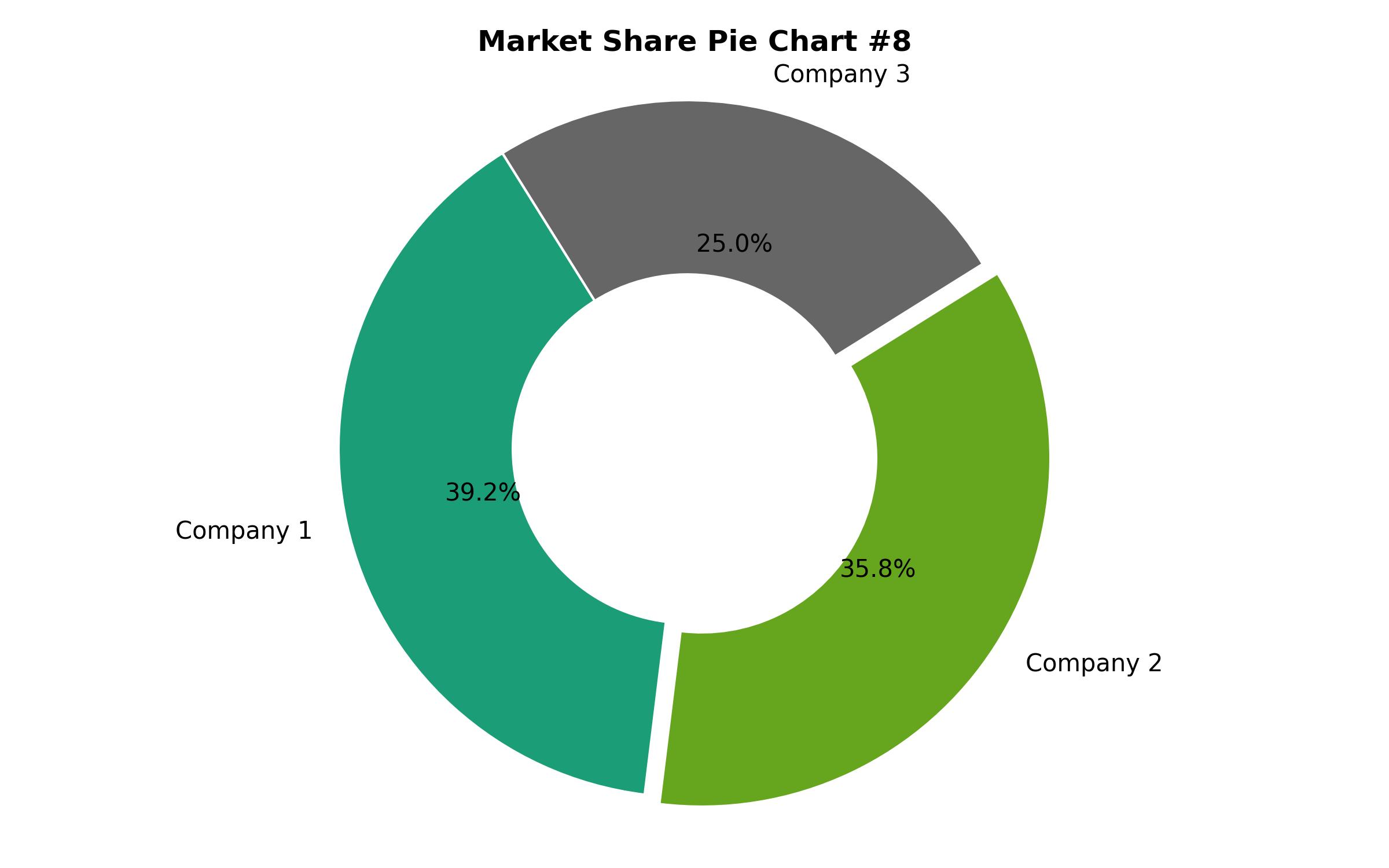

Key Companies Market Share

Report Coverage & Deliverables

- Market Trends And Dynamics

- Competitve Benchmarking

- Historical data and forecasts

- Value/Volume analysis

- Company revenue shares and key strategies

- Regional opportunities

This is an indicative segmentation. Please request a sample report to see detail segmentation of this market.

Detailed Market Segmentation

- By Hardening Type

- Age Hardening

- Artificial Aging

- Natural Aging

- By Material

- Aluminum Alloys

- Steel Alloys

- Nickel Alloys

- Titanium Alloys

- By End-Use Industry

- Aerospace

- Automotive

- Oil and Gas

- Construction

- Defense

- By Region

- North America (U.S., Canada, Mexico)

- Europe (U.K., Germany, France, Italy, Poland)

- Asia-Pacific (China, India, Japan, Australia, South Korea)

- Latin America (Brazil, Argentina)

- Middle East & Africa (MEA) (UAE, Saudi Arabia, South Africa)

Table of Content

- Executive Summary

- Market Dynamics

- Key Market Drivers

- Restraints and Challenges

- Emerging Opportunities

- Market Size and Forecast

- Market Analysis by Hardening Type

- Age Hardening Analysis

- Artificial Aging Analysis

- Natural Aging Analysis

- Market Analysis by Material

- Aluminum Alloys Analysis

- Steel Alloys Analysis

- Nickel Alloys Analysis

- Titanium Alloys Analysis

- Market Analysis by End-Use Industry

- Aerospace Industry Analysis

- Automotive Industry Analysis

- Oil and Gas Industry Analysis

- Construction Industry Analysis

- Defense Industry Analysis

- Market Analysis by Region

- North America Market Analysis

- Europe Market Analysis

- Asia-Pacific Market Analysis

- Latin America Market Analysis

- Middle East & Africa Market Analysis

- Competitive Landscape

- Key Company Profiles

- Industry Trends and Developments

- Strategic Recommendations

- Research Methodology